We provide top-notch manufacturing and design solutions, ensuring high-quality and precision engineering for industrial applications.

At Visiotrix, we offer comprehensive IoT product design and manufacturing services tailored to meet the demands of industrial environments. Our end-to-end solutions cover every stage of development—from concept to mass production. We begin by understanding your requirements and translating them into robust hardware and software architecture. Our team designs compact and efficient embedded systems, incorporating microcontrollers, sensors, wireless modules (such as Wi-Fi, BLE, LoRa, or GSM), and custom PCBs optimized for industrial use. Alongside hardware, we develop secure and reliable firmware that ensures real-time data acquisition, sensor calibration, and wireless communication.

By automating routine operations and enabling real-time data acquisition and control, process plant automation enhances productivity, reduces human errors, and ensures consistent product quality. It also improves safety by allowing for early detection of faults or abnormal conditions and supports compliance with industry regulations. Additionally, automation provides valuable analytics and reporting tools that help operators make informed decisions, plan maintenance, and optimize energy usage. With the integration of IoT and cloud technologies, modern automation systems are also capable of remote monitoring and predictive maintenance, paving the way for smart and sustainable plant operations.

Our control panel manufacturing services provide robust and reliable solutions for industrial automation. We specialize in designing and fabricating customized control panels that meet the specific needs of various industries.Precision and adherence to electrical standards are key in control panel manufacturing. Proper layout design, cable routing, labeling, and enclosure selection not only enhance functionality but also simplify maintenance and troubleshooting.Modern control panels often integrate features like remote monitoring, touchscreen interfaces, and modular wiring to support advanced automation systems. Rigorous quality checks, including insulation resistance, continuity, and functional testing, ensure that the panel performs flawlessly in real-world conditions.

With the growing demand for smart manufacturing and energy-efficient systems, control panel manufacturing continues to evolve, incorporating IoT connectivity and intelligent diagnostics for enhanced performance and operational insight.

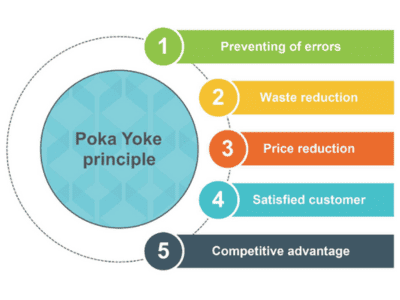

Poka Yoke, a Japanese term meaning "mistake-proofing" or "error prevention," is a key concept in lean manufacturing aimed at eliminating human errors in production processes. It involves designing simple, fail-safe mechanisms or procedures that either prevent mistakes from occurring or immediately detect and correct them before they result in defects. Poka Yoke devices can be mechanical, electrical, or software-based and are typically integrated into workstations, machines, or inspection systems.

Examples include jigs that ensure correct part placement, sensors that verify component orientation, or interlocks that prevent a machine from operating unless all conditions are met. By implementing Poka Yoke techniques, manufacturers can significantly reduce waste, improve quality, and enhance overall process reliability. It empowers workers by simplifying tasks, reducing reliance on memory or judgment, and fostering a proactive quality culture. Whether used in automotive assembly, electronics, packaging, or industrial automation, Poka Yoke contributes to consistent production standards and supports continuous improvement initiatives across all levels of operation.