Plant and Automation refers to the integration of advanced control systems, machinery, and digital technologies within an industrial plant to streamline operations, enhance productivity, and ensure consistent quality. By automating processes such as material handling, production monitoring, and data acquisition, industries can reduce manual intervention, minimize errors, and improve overall efficiency. Automation systems like PLC (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and HMI (Human Machine Interface) play a vital role in controlling and supervising various plant operations in real-time. This transformation not only ensures optimal resource utilization but also enhances safety, reduces downtime, and supports predictive maintenance, making modern plants smarter and more sustainable.

Why Choose Automation?

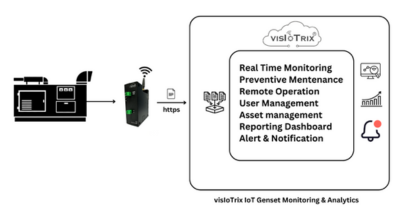

Automation in a plant environment offers multiple benefits. It increases operational speed and accuracy, reduces human error, enhances safety, and lowers production costs. With the introduction of Industrial IoT (IIoT), plants are becoming even more intelligent—enabling real-time data analytics, predictive maintenance, remote monitoring, and seamless communication between devices and systems. This digital transformation leads to better quality control, faster production cycles, and greater flexibility to adapt to market demands.

IAPL Digital Work Instructions revolutionize the way your team performs tasks, merging simplicity with innovation to drive operational excellence. Our platform transforms traditional, cumbersome procedures into straightforward, digital guides, ensuring precision and efficiency at every step.

Digital Work Instructions (DWI) are electronic, interactive guides used to standardize and streamline tasks across manufacturing, maintenance, and assembly processes. Unlike traditional paper-based instructions, digital work instructions offer dynamic, real-time guidance with visual aids such as images, videos, animations, and step-by-step instructions displayed on screens, tablets, or smart devices. This modern approach significantly reduces errors, ensures consistent quality, and speeds up training for new operators. Digital instructions can also be updated instantly, allowing for quick adjustments in response to process changes or design modifications.

At Visiotrix, we do Production OEE (Overall Equipment Effectiveness) implementation to help industries maximize productivity and reduce losses across their manufacturing operations. We focus on the three essential pillars of OEE—Availability, Performance, and Quality—by collecting real-time data from machines and production lines. Our smart systems provide detailed insights into machine downtimes, production speed losses, and quality rejections, enabling plant managers to make informed decisions and improve overall efficiency.

With intuitive dashboards and analytics tools, we help identify bottlenecks, monitor equipment health, and optimize production schedules. Our OEE solutions integrate seamlessly with existing PLC, SCADA, and IoT infrastructures, offering scalable and flexible deployment tailored to each client’s unique process. At Visiotrix, we believe in data-driven manufacturing that supports continuous improvement, minimizes waste, and drives operational excellence.

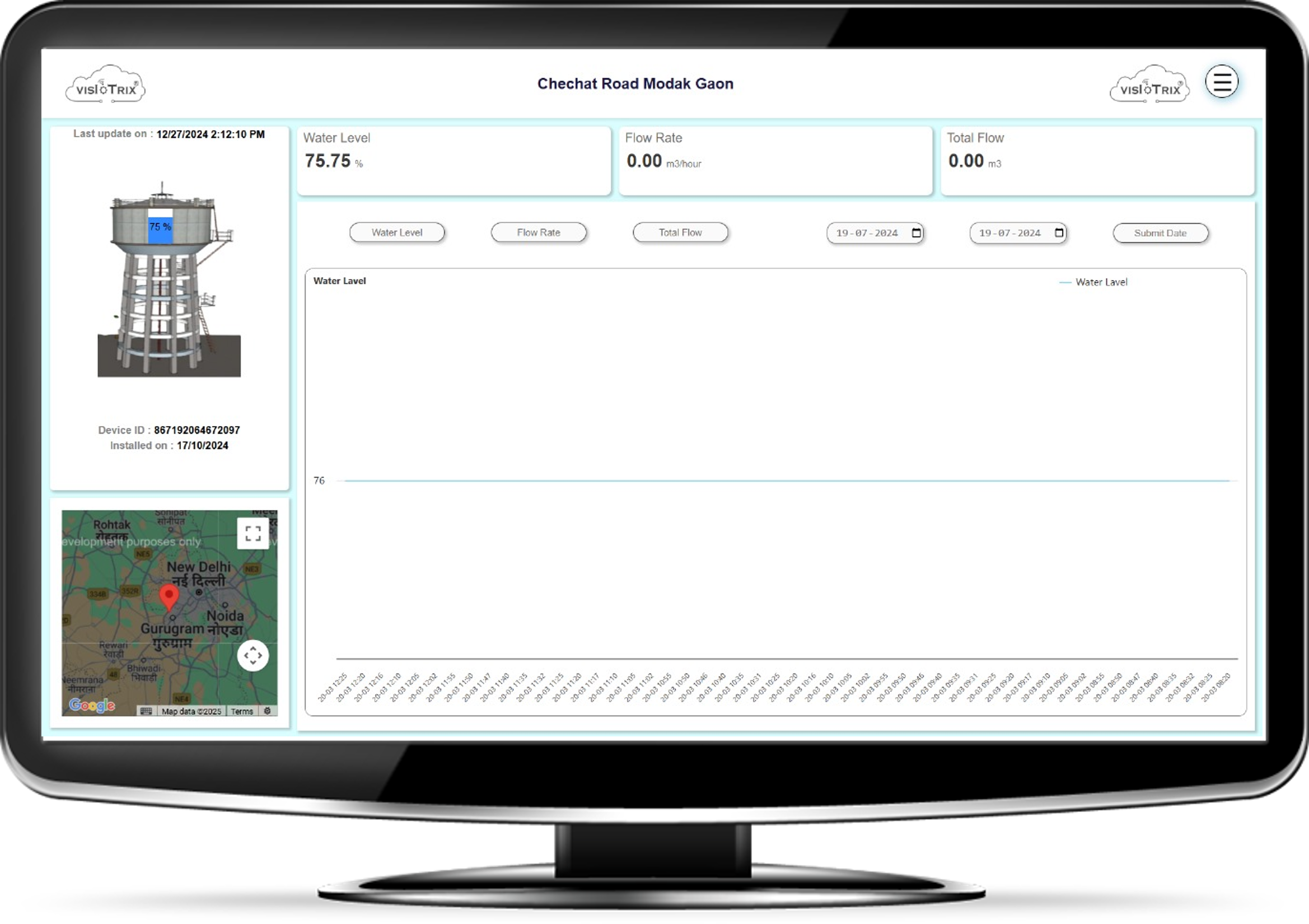

At Visiotrix, we offer advanced Utility Monitoring solutions designed to track and analyze the consumption of key resources such as electricity, water, compressed air, steam, and gas across industrial facilities. By leveraging smart meters, sensors, and real-time data acquisition systems, we provide detailed visibility into energy usage patterns, inefficiencies, and potential leakages.

Our solutions help industries reduce energy costs, optimize resource utilization, and support sustainability initiatives. With user-friendly dashboards and alerts, plant managers can monitor utility performance 24/7, set benchmarks, and take timely corrective actions. Whether it's peak demand management, load balancing, or utility cost allocation, our monitoring systems are built to deliver accurate, actionable insights that enhance operational efficiency and reduce environmental impact.

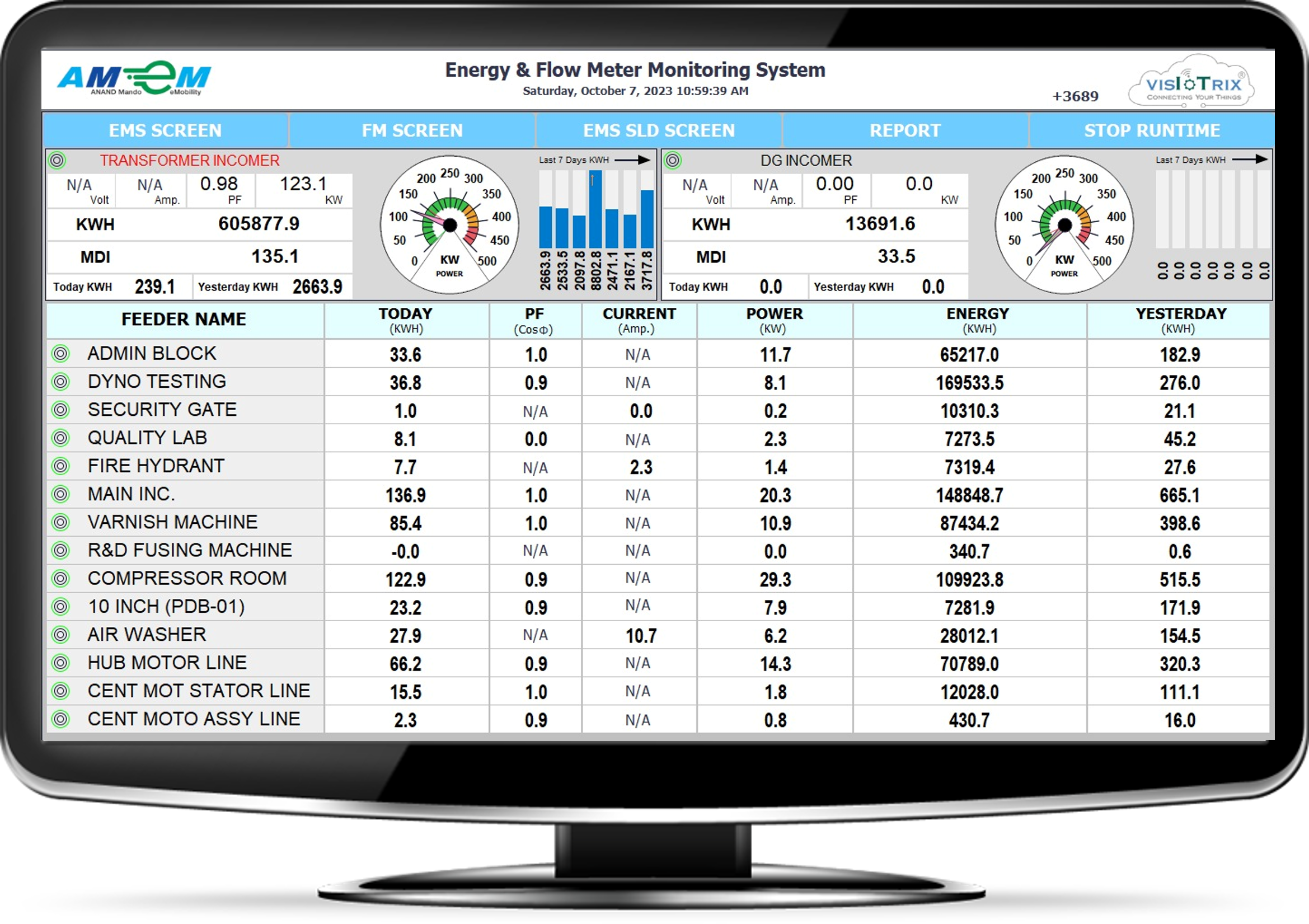

At Visiotrix, we deliver intelligent Energy Monitoring solutions that empower industries to gain real-time insights into their power consumption and electrical efficiency. Our systems are designed to monitor critical parameters such as voltage, current, power factor, frequency, and energy consumption across machines, processes, and departments.

By integrating advanced metering infrastructure with data analytics, we help organizations identify power wastage, track energy trends, and make data-driven decisions to improve energy efficiency. Our intuitive dashboards and customizable reports provide actionable visibility that supports compliance, cost reduction, and sustainability goals. Whether you're managing a single facility or a network of plants, Visiotrix ensures your energy usage is optimized, controlled, and aligned with your operational objectives.

At Visiotrix, we provide precise and reliable Temperature Monitoring solutions designed for critical industrial applications. Our systems continuously track temperature levels across machinery, processes, and environments, ensuring optimal performance and safety. With advanced sensors and real-time data logging, we enable industries to maintain consistent thermal conditions, prevent equipment overheating, and comply with regulatory standards.

Integrated alerts and remote monitoring capabilities help in early detection of anomalies, reducing downtime and improving process efficiency. Whether for manufacturing lines, server rooms, or HVAC systems, Visiotrix’s temperature monitoring solutions ensure consistent quality control and operational excellence.

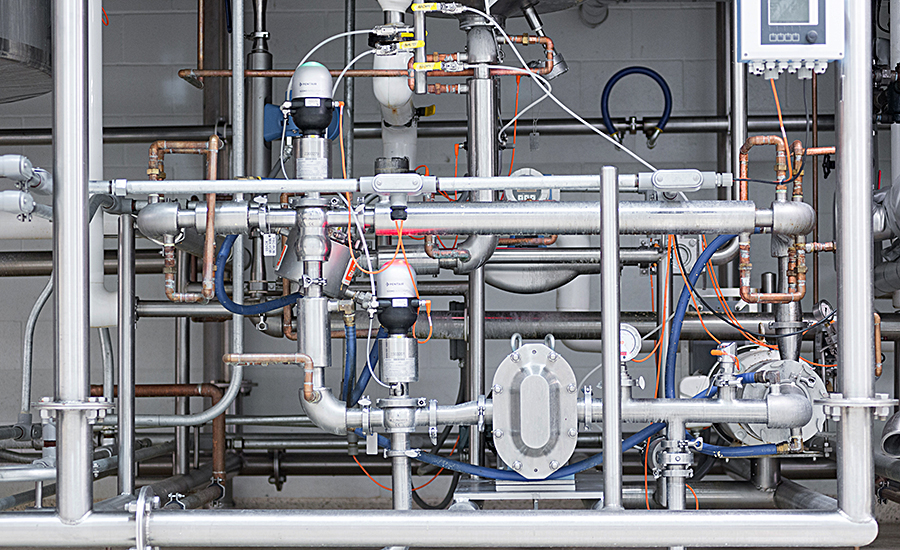

At Visiotrix, we deliver advanced Flow Rate Monitoring solutions that enable accurate measurement and control of liquid and gas flow within industrial processes. Our systems are engineered to ensure efficient resource utilization, detect leaks, and maintain optimal operating conditions across pipelines and production systems.

With real-time data acquisition and integration into SCADA or IoT platforms, our flow monitoring technology supports predictive maintenance and process optimization. From water treatment plants to chemical manufacturing units, Visiotrix ensures that your flow systems operate with precision, reliability, and complete transparency for smarter industrial operations.

Enhance Water Management with Smart Pump & Tubewell Monitoring Optimize water usage and prevent resource wastage with IAPL’s advanced Pump & Tubewell Monitoring solutions. Our system ensures real-time tracking of pump performance, water levels, and operational efficiency.

We offer advanced DG Monitoring solutions designed to optimize the performance and efficiency of your diesel generators. Our service ensures that your backup power systems are always ready, running cost-effectively, and compliant with environmental standards.

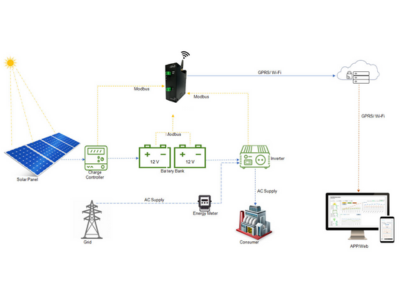

Our Solar Monitoring solutions are engineered to ensure your solar energy systems deliver peak performance and maximum savings. With real-time data and comprehensive analytics at your fingertips, you can optimise your solar investment and advance your journey toward sustainability.

In today’s competitive business landscape, efficiency and accuracy are key. At IAPL, we specialize in implementing cutting-edge barcode and RFID technology to revolutionize your inventory, asset management, and security processes.

Barcode Technology: A time-tested method for encoding data visually for quick machine readability, enhancing operational efficiency.

RFID Technology: Uses electromagnetic fields for automatic identification and tracking, allowing for seamless inventory management without direct line-of-sight scanning.

Benefits:

Efficient inventory management is the backbone of a successful business. At IAPL, we provide cutting-edge solutions that optimize stock levels, reduce waste, and enhance operational accuracy.

Key Features:

Why Choose IAPL?

Our inventory management system is tailored to streamline your workflow, minimize stock discrepancies, and enhance overall efficiency. Upgrade your inventory control with IAPL’s intelligent solutions today!

At IAPL, we prioritize workplace wellness through proactive health maintenance planning. Our solutions ensure employee well-being while enhancing operational efficiency.

Key Benefits:

Transform your workplace health planning with IAPL’s innovative strategies and ensure a healthier, more productive workforce.

Efficient inventory management is the backbone of a successful business. At IAPL, we provide cutting-edge solutions that optimize stock levels, reduce waste, and enhance operational accuracy.

Key Features:

Why Choose IAPL?

Our inventory management system is tailored to streamline your workflow, minimize stock discrepancies, and enhance overall efficiency. Upgrade your inventory control with IAPL’s intelligent solutions today!